Most contractors have reported a schedule savings of 8 weeks or more when they opted for CFS Prefabricated Wall Panel Construction.

Build Faster

Save Money

Fewer Headaches

Compared to stick framing, more CFS wall square footage can be set each day. Less curing downtime makes CFS faster than concrete, too.

Offsite manufacturing utilizes BIM and precise 3D modeling to keep MEP on track. This also makes sure that trades are not interrupted

The Wall-tech enclosure system is 30-40% cheaper than concrete. Average savings of $9/sq ft.

.jpg)

At Wall-panel Prefab, We understand what it's like to deal with unpredictable schedules and project management headaches. We are construction veterans who've been in business for 35+ years and are a recognized leader in CFS prefabrication

Our team of experts in pre-planning, pre engineered construction, structural framing contractor, load bearing wall, exterior wall framing and project management can provide you with a tailored CFS framing solution to match your project. Your building will be completed faster and with superior quality.

Talk to us today so you can stop micromanaging slow projects and start delighting your clients with an on-time, on-budget delivery.

We'll take some time to learn more about you and your project

A customized integrated plan that fits your specifications, your budget, and your schedule.

We guarantee that your building will be enclosed in half the time and on budget

Metreau Apartments, Greenbay, WI - CFS enclosure resulted in $250k savings and an early delivery.

CFS provided more stories than wood without the need to pay a premium for concrete and the additional parking that 10-stories would have required. With CFS, the developer got better flexibility in floor count and parking requirements.

Prefabricated CFS framing for a mid-rise building

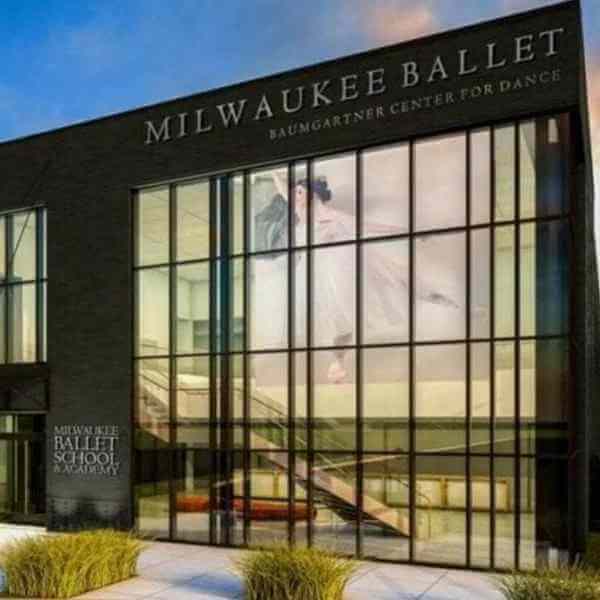

Rendering of the Baumgartner Center for Dance. CFS Enclosure 40-day schedule … finished in just 7 days.

Learn More

Complete the form below to receive the free PDF download

6135 N. American Lane Deforest, WI 53532 608-257-1595

Other locations

Copyright 2024 Wall-tech and Wall-panel

All rights reserved